In modern logistics and production facilities, palletizers serve as indispensable mechanical giants. These tireless systems precisely stack products – from beverage cases to chemical sacks and delicate electronics – creating stable pallet loads for storage and transport. As automation transforms global industries, palletizer varieties have diversified to meet countless application needs. Understanding these “mechanical arms” is crucial for optimizing workflows and boosting efficiency.

I. Structural Forms: The Framework Dictating Function

The core distinction between palletizers lies in their mechanical architecture, determining movement patterns, operational range, and load capacity.

- Cartesian Palletizers:

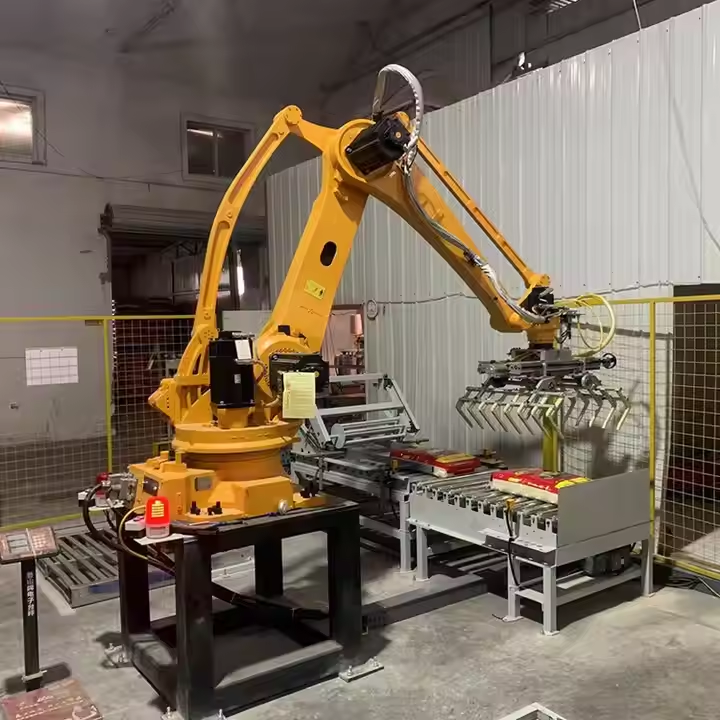

These classic systems feature a gantry spanning the work area. Operating along straight X/Y/Z axes (sometimes with rotational axes), they deliver rigidity and stability. Ideal for uniform cases like food/beverage packaging, they excel in high-speed, high-precision repetitive tasks. Available in sizes from compact to industrial-scale, they handle loads from lightweight to exceptionally heavy materials like construction components. - Articulated Robot Palletizers:

Mimicking human arm structure with rotating joints, these offer unparalleled flexibility. Their multi-axis design enables complex maneuvers through confined spaces, perfect for irregular stacking patterns, product rotation, or mixed-SKU pallets. Though not always the fastest option, their adaptability increases overall efficiency in industries like cosmetics, pharmaceuticals, and flexible manufacturing. - SCARA Palletizers:

Selective Compliance Assembly Robot Arms feature parallel rotational joints for horizontal movement with vertical linear motion. Renowned for rapid horizontal precision, they specialize in lightweight item stacking like electronics and small packages where vertical rigidity is less critical. - Gantry Palletizers:

Essentially reinforced Cartesian systems, these feature robust frameworks spanning large areas via overhead rails. With extended vertical reach, they dominate heavy industrial applications – handling massive tires, machinery parts, or bulk chemical sacks where extreme load capacity is paramount. - Delta Parallel Palletizers:

Distinguished by lightweight arms connected to moving platforms, these high-speed specialists deliver astonishing acceleration. Designed for ultralight packaging like snack bags, pharmaceuticals, and confectionery, they perform lightning-fast palletizing in food/pharma industries.

II. Gripping Methods: Adapting to Product Diversity

Different “hands” enable palletizers to handle varied loads:

- Clamp Grippers: Pneumatic/electric jaws grip rigid boxes and cartons – reliable and adjustable.

- Vacuum Systems: Suction cups lift smooth-surfaced items, while foam pads handle uneven bags like flour/feed sacks.

- Push Plates: Hydraulic/pneumatic rams slide unstable soft bags into position without direct handling.

- Hybrid/Custom Tools: Combined grippers or specialized attachments manage unique items like barrels, pipes, or mixed loads.

III. Deployment Configurations: Layout Integration

Integration methods determine operational flexibility:

- In-line Systems: Directly connected to production lines for real-time synchronization – maximum efficiency.

- Off-line Stations: Independent units drawing from buffer zones – ideal for multi-line feeding or maintenance flexibility.

- Mobile Units: Robotic arms mounted on autonomous vehicles (AMR/AGV) – deliver palletizing capabilities anywhere in facilities.

IV. Industry Applications: Universal Stacking Solutions

Palletizers serve virtually all sectors requiring organized pallet loads:

- Food/Beverage: High-speed can/bottle stacking to bagged goods handling

- Chemicals: Heavy-duty bag/barrel stacking in harsh environments

- Pharma: Precision handling in sterile environments

- Building Materials: Cement/tile palletizing

- E-commerce: Intelligent parcel stacking with vision systems

V. Selection Strategy: Matching Needs

Choosing requires evaluating:

- Product characteristics (weight/size/shape)

- Throughput requirements

- Pattern complexity

- Space constraints

- Environmental conditions

- Budget/ROI considerations

VI. Future Evolution: Smarter, More Adaptive

Emerging technologies include:

- 3D vision-guided random picking

- AI-optimized stacking patterns

- Digital twin simulations

- Energy-efficient designs

- Collaborative palletizing robots

Conclusion

From Cartesian workhorses to nimble Delta systems, palletizers have evolved into sophisticated solutions blending mechanics, sensing, and intelligence. Understanding their capabilities helps businesses build efficient, future-ready operations. At Yuhang Technology, we leverage China’s manufacturing excellence to deliver versatile palletizing solutions that enhance global supply chain resilience.

Leave a Comment

Your email address will not be published. Required fields are marked *