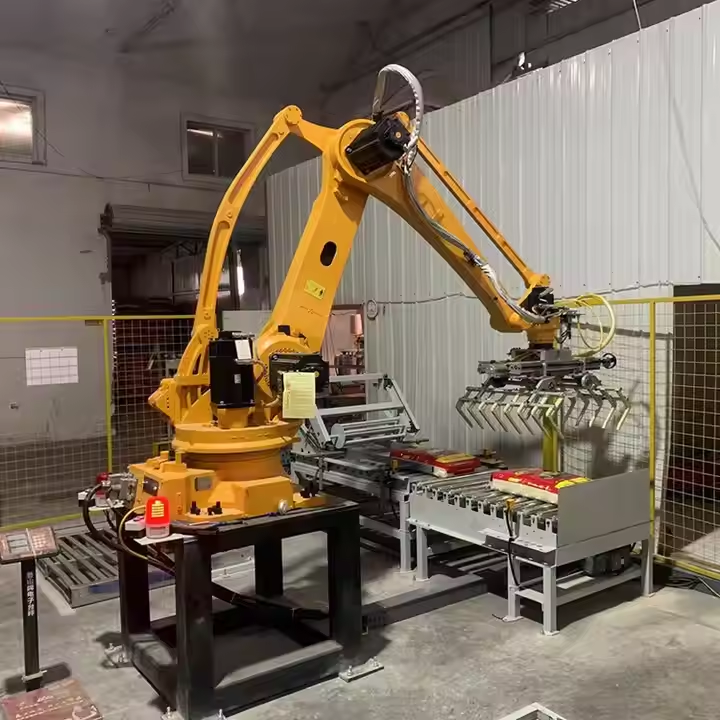

In the heart of modern factories and distribution centers, robotic palletizers have evolved from novel equipment to essential productivity engines. These intelligent systems outperform traditional methods through five transformative advantages that redefine logistics efficiency.

1. Unmatched Flexibility & Adaptability

3D Movement Mastery

Multi-joint designs (4-6+ axes) enable fluid movement in confined spaces – rotating, extending, and reaching where fixed systems cannot. This allows:

- Complex stacking patterns (interlocked, rotated, or mixed-SKU pallets)

- Operation around existing equipment without line reconfiguration

- Simultaneous servicing of multiple conveyors at varying heights

Intelligent Vision Integration

2D/3D vision systems enable:

- Random bin picking of disorganized items

- Real-time position correction for misaligned packages

- Automated product sorting during palletizing

Rapid Changeover Capability

- Program-based adjustments replace mechanical reconfiguration

- Universal grippers handle diverse packaging formats

- <5-minute product changeovers support high-mix production

2. Precision Performance

Reliable Throughput

- Consistent 24/7 operation at optimized speeds

- ±0.1mm repeat positioning accuracy

- Predictive maintenance minimizes unplanned downtime

Optimized Motion Efficiency

- AI-path planning reduces cycle times by 15-30%

- Smooth acceleration curves prevent product damage

- Continuous operation maintains line balance

3. Operational Cost Transformation

Labor Optimization

- Replaces 3-5 manual workers per shift

- Eliminates ergonomic injuries from heavy lifting

- Operates in harsh environments (-20°C to 50°C)

Total Cost Reduction

- 30-50% lower product damage versus manual handling

- 20% higher trailer space utilization through perfect stacking

- Reduced training costs with intuitive programming

4. Quality Assurance

Process Consistency

- Eliminates human performance variability

- Maintains GMP compliance in pharma/food sectors

- Generates digital pallet records for full traceability

Contamination Control

- Minimal human-product contact

- Cleanroom-compatible models available

- IP67 protection for washdown environments

5. Future-Ready Platform

Industry 4.0 Integration

- OPC-UA communication for MES/ERP connectivity

- Real-time production analytics dashboard

- Predictive maintenance alerts

Scalable Intelligence

- Machine learning optimization of stacking patterns

- Digital twin simulation for layout planning

- Collaborative models (cobots) for hybrid workcells

Strategic Impact

Robotic palletizers deliver compounding returns:

- 12-18 month ROI through labor/productivity gains

- 30% throughput increase via uninterrupted operation

- Future-proof scalability for evolving logistics needs

At Yuhang Technology, we engineer palletizing solutions that harness these advantages. Our Chinese-manufactured systems combine precision engineering with intelligent software, helping global operations build resilient, efficient supply chains.

Leave a Comment

Your email address will not be published. Required fields are marked *