Description

Model | YH-R120 | YH-R180 |

| Working radius | 2400mm | 3200mm |

| Maximum carrying weight | 120 kg | 180 kg |

| Power capacity | 20 KVA | 27 KVA |

| Body weight | 1020 kg | 1150 kg |

| Power | 18.5kw | 18.5kw |

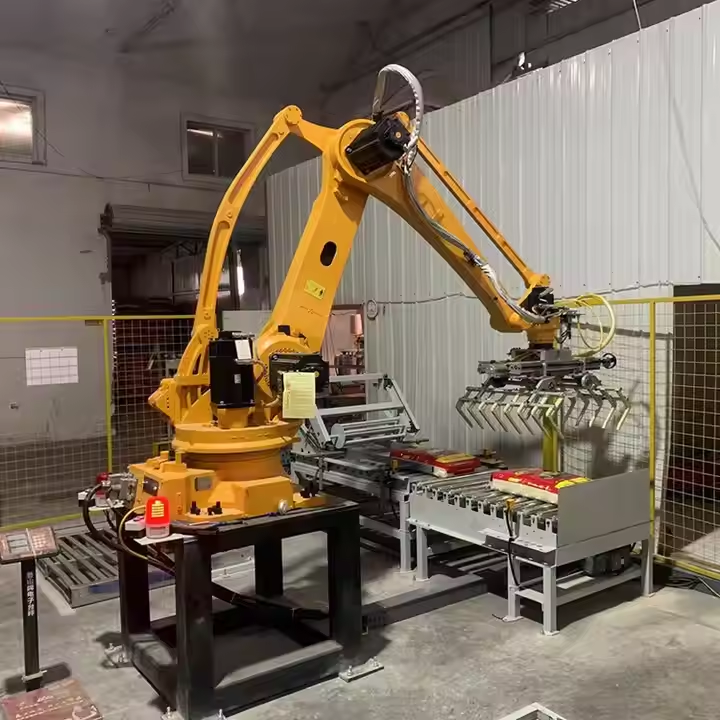

Type | Vertical joint 4 DOF | |

| Main functions | handling, palletizing, loading and unloading | |

| Position repeatability | ±0.2mm | |

| Use environmental conditions | 0-45℃ , 20-80%RH (no condensation phenomenon) | |

| Protection level | Equivalent to IP54 | |

| Applicable industries | packaging, chemical industry, metallurgy, casting, construction, cement, feed etc. | |

Advantages of Palletizing Robots

Automatic palletizers generally offer many benefits in a packaging or production line. They make manufacturing processes more efficient and eliminate the human factor that can slow down the plant‘s rate of operation. With the derived benefits, palletizers can easily surpass the required investment cost. The advantages of using palletizers include:

Increased Pr oductivity:

oductivity:

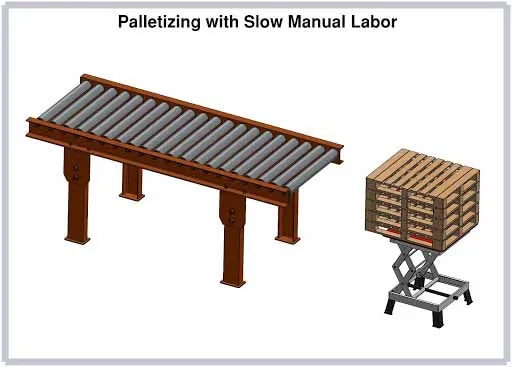

Palletizers eliminate manual labor for unitizing products. They are much more efficient, lift heavier loads, and perform the work faster. They also do not experience exhaustion or injury. With proper maintenance, palletizers can reliably operate 24/7. This

reduces any potential bottlenecks in the packaging line.

Better Product Handling:

Since palletizers are automated machines, their movements are pre-programmed and are designed to function without damaging the product. They do not need to constantly make decisions, unlike their human counterparts. This makes them less prone to errors resulting in better product handling.

Improved Workplace Safety:

When properly designed, palletizers eliminate workplace threats and hazards associated with manual labor. Manual palletizing poses falling, slipping, tripping, and crushing hazards. They also cause muscle strains due to the repetitive reaching and stacking of products. This can lead to lower back injuries and can permanently damage the health of workers.

Reduced Operating Costs:

In most applications, particularly in large packaging systems, the cost-benefit analysis of acquiring a palletizer yields positive results. Savings in operating expenses can be derived from increased throughput, low product wastage, and reduced labor costs.

Differences of Robotic Palletizer and Conventional Palletizer

If the above qualities are not enough, there are also some advantages unique to robotic palletizers. When purchasing a palletizer, the first question that comes to mind is which type of palletizer to buy. Thus, it is important to know the pros and cons of robotic and conventional palletizers. Each type has its own merits that make it suitable for a particular application. The table below compares the two pieces of equipment.

Robotic Palletizer | Conventional Palletizer |

| Low investment cost for simple applications: For simple palletizing solutions, a robotic arm can be employed where speed is not a critical factor. Using a robotic arm eliminates the need for multiple conveying systems, turning mechanisms, stoppers, gates, and so forth. Thus, robotic arms are a cheaper option when they can cope with the required throughput. | Better tolerance with varying packaging types: Conventional palletizers form the unit load by turning and pushing the product to its desired location and orientation without the need to pick up and place the product. Thus, varying the packaging dimensions or packaging types will not affect the handling of the palletizer. If modification is needed, this can be done by adjusting the controls through its program. No hardware modification is needed. |

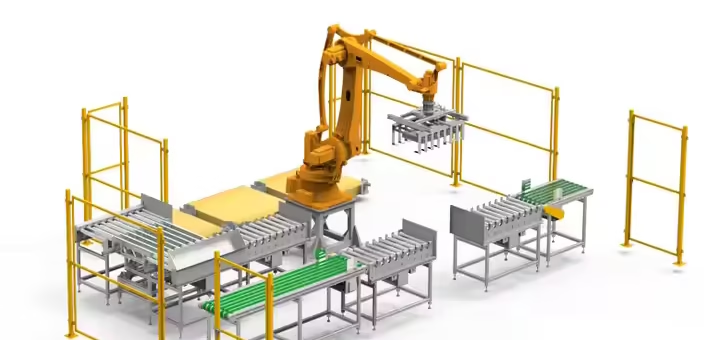

| Ability to serve multiple lines: One robotic palletizer can be situated between two or more packaging lines. For one conventional palletizer to serve multiple lines, upstream product accumulation systems are used. Robotic palletizers eliminate this need which further cuts the investment cost. | Higher throughput: Most conventional palletizers are used for high throughput palletizing. This is because their actuators’ movements are much simpler than that of robotic types. Moreover, they can easily transfer and orient multiple products at once. Robotic palletizers, on the other hand, are slow if their mode of operation is individually picking and placing products. They can only increase their throughput rate by collecting multiple products at the same time. |

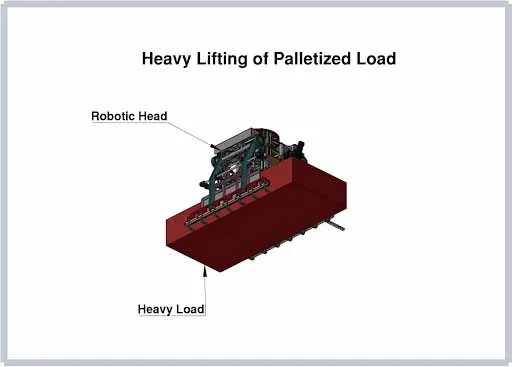

| Versatile pattern forming: Robotic palletizers are better equipped to change pattern formation than conventional palletizers. Changing the pattern only requires reprogramming of the robotic arm’s movement and the actuation of the end effector. There is no need to change its hardware. However, changing the palletizing pattern can cause negative effects on its throughput. | More robust and reliable: Conventional palletizers are fit to handle heavier loads than robotic palletizers with similar capacities. In a conventional palletizer, the bulk of the load is carried by a conveyor system that easily handles weights far above the pallet load. In contrast, robotic systems have loads that are concentrated at their joints. This is especially significant for robots with articulated arms. Moreover, the joints of a robotic arm perform more movements for a given operation. Fatigue due to dynamic mechanical stresses is more evident in robotic types. |

| Ability to perform secondary tasks: Robotic palletizers equipped with vacuum, magnetic, or custom end-of-arm-tools can perform additional tasks such as slip sheet dispensing, pallet placing, and wrapping. Aside from these additional functions, robotic palletizers can completely reverse their operation. This feature is seen on robotic palletizers-depalletizers. | Easy maintenance and servicing: Conventional palletizers are easy to troubleshoot. They have several actuators that perform distinct functions. Determination of which actuator failed is accomplished by simply observing the operation of the machine. In addition, conventional types have more hardwired components than robotic types. Servicing hardwired components requires less technical specialization. |

| More compact: Robotic palletizers are more compact than conventional types. They only take up the space required by the robotic arm and the staging platform for the palletized load. Conventional types have many different components such as conveyors, pushers, and ejectors; these are all required for accomplishing a single operation. This configuration takes up significant floor area and headroom. They also have multiple staging areas for layer forming. | Easy part replacement and sparing: Most conventional palletizer actuators are on the market. These actuators are more common since their application is not limited to palletizers. Large supplies are available because of the high demand. Most manufacturers of robotic palletizers use patented parts, which usually have limited suppliers. |

There are no reviews yet.