The Unshakable Backbone of Automation: Core Advantages of Column Palletizers

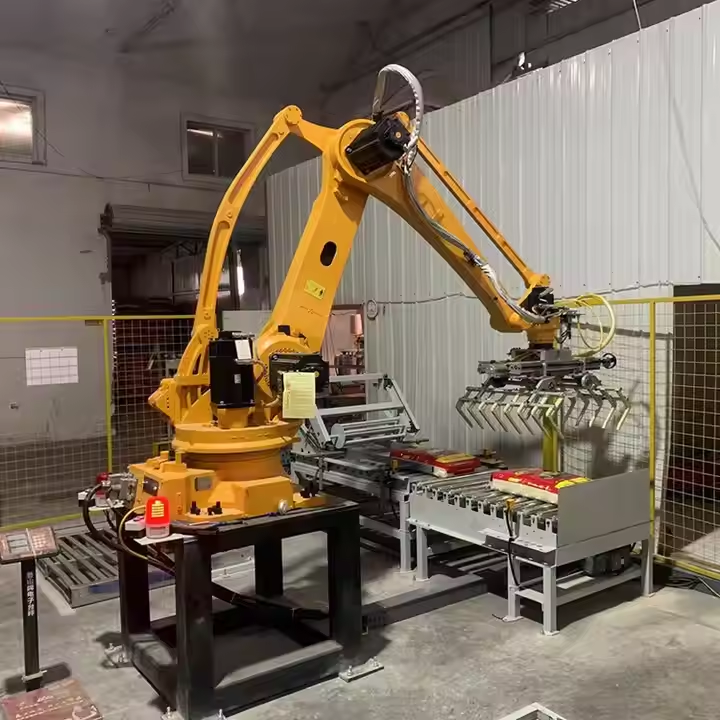

While robotic arms capture attention with their flexibility, column palletizers remain the unsung heroes of heavy-duty industrial automation. These robust systems deliver unparalleled reliability where it matters most – in high-volume production environments demanding unwavering stability and efficiency. At Yuhang Technology, we’ve engineered column palletizers that embody China’s precision manufacturing capabilities while addressing global industrial needs.

I. Structural Superiority: The Foundation of Reliability

Vertical Column Design Advantages

- Extreme Load Capacity: Handles 50-1000kg unit loads (building materials, chemical drums, automotive components)

- Vibration Resistance: <0.5mm deviation during high-speed operation

- Maintenance Efficiency: 30% fewer moving parts vs. articulated robots

Industrial Impact: Chinese manufacturing refinements have enhanced structural integrity while reducing steel usage by 15% through computational optimization.

II. Performance Excellence in Demanding Environments

Optimized for Continuous Operation

- Speed & Precision: 80+ cycles/minute with ±0.5mm repeatability

- Motion Efficiency: Linear axis movement reduces energy consumption 25% vs. robotic systems

- 24/7 Durability: Tested for 100,000+ hours in cement and chemical plants

Real-World Example: A beverage facility achieved 99.3% uptime using column palletizers for 20kg crate handling.

III. Operational Cost Advantages

Total Ownership Benefits

| Advantage | Impact | Sector Example |

|---|---|---|

| Labor Reduction | 3-5 operators replaced | Food packaging |

| Damage Prevention | <0.2% product loss | Electronics |

| Space Optimization | 40% smaller footprint | Compact facilities |

| Energy Efficiency | 15-30% lower consumption | Sustainable operations |

Maintenance Advantage: Simplified components enable faster repairs – critical spare parts changeover in <30 minutes.

IV. Specialized Environmental Adaptation

Engineered for Extreme Conditions

- Protection Systems: IP66-rated models withstand washdowns (dairy/pharma)

- Corrosion Resistance: Stainless steel variants for chemical plants

- Low-Temperature Operation: -30°C performance for frozen food logistics

Yuhang Innovation: Our patented sealing systems extend bearing life 2X in high-humidity environments.

V. Industry-Specific Solutions

Dominant Applications

- Beverage Industry: 2000+ bottles/hour palletizing

- Building Materials: 50kg cement bag stacking

- Automotive: Engine block palletizing

- Bulk Logistics: Standardized container loading

Operational Comparison

| Metric | Column Palletizer | Robotic Arm |

|---|---|---|

| Max Payload | 1000kg | 300kg |

| Speed (boxes/hr) | 3000+ | 1500 |

| Footprint | Compact | Large safety zone |

| Changeover | Program-based | Mechanical + program |

Strategic Value Proposition

Column palletizers deliver compounding returns:

- <18 month ROI through labor and efficiency gains

- 99%+ operational reliability in continuous processes

- Future-ready platforms supporting IIoT integration

At Yuhang Technology, our column palletizers incorporate China’s manufacturing excellence in precision engineering and value optimization. Designed in Shanghai and validated in global operations, they represent the perfect balance of Eastern efficiency and industrial durability.